Isolation Procedure

1. Objective

This procedure describes the process used for electrical and mechanical isolations, to ensure all electrical and mechanical work is carried out in a safe manner with appropriate controls in place.

The primary objective of isolating the equipment is to avoid machinery being accidentally started or systems accidentally powered during repair and maintenance – no matter how small the job is – and no matter how short time the job is going to take. The systems must be isolated before the commencement of work that involves contact with moving or powered components.

This procedure defines the circumstances where isolation as a minimum is required. If isolation is required by law, contract terms and conditions, or if deemed appropriate by the responsible supervisor or the staff assigned for the job, such requirements are complied with.

2. Responsibility

| Role | Responsibility | Position |

| Responsible Supervisor | The Responsible Supervisor has overall responsibility for the implementation of this procedure.

Responsibilities:

|

|

| PTW Holder | A person who applies for PTW and executes or supervises the work

Responsibilities: The Person Performing the Work is responsible to ensure that only work in accordance with the description on the Isolation Certificate is performed. The Person Performing the Work works under the direction of the Isolator when breaking containment and fitting isolation devices. |

|

| Isolator | The person performing either Mechanical or Electrical Isolation.

Responsibilities: The Isolator is responsible for the specification, application, removal, and recording of Mechanical Isolations. He must demonstrate to the PTW Holder that isolations have been carried out successfully and are secure. |

|

| PTW Administrator | The person who is responsible for the administration of all the works covered by PTW. PTW Administrator is a focal point between all affected parties.

Responsibilities:

|

|

3. Procedure

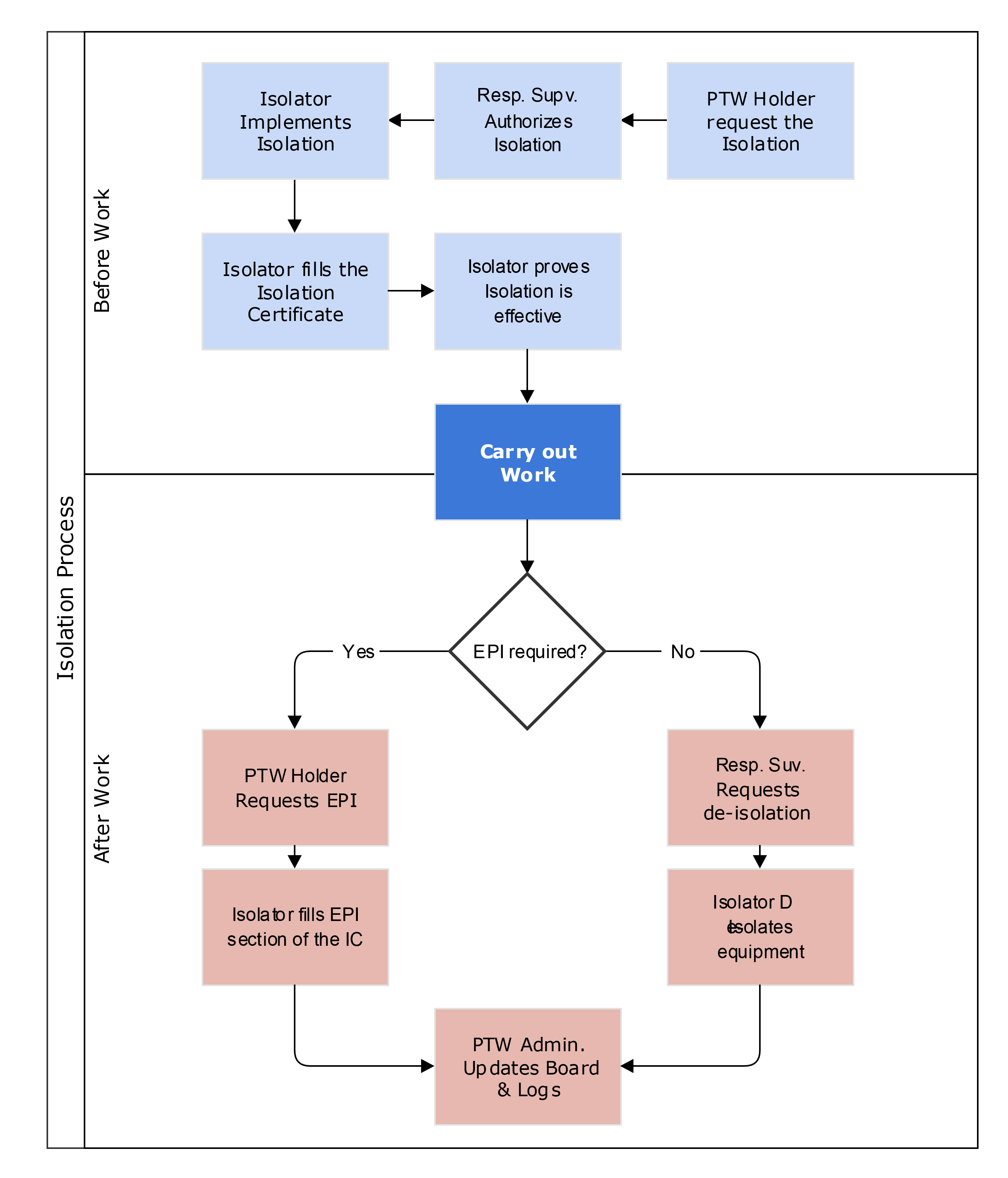

The Isolation Certificate must be applied for together with a Work Permit. Isolation flowchart to be used for the process

0.1. Applying for an Isolation Certificate

- The Applicant accesses the Isolation Certificate via the Work Permit form.

- The Applicant fills in the sections:

- Isolation Certificate

- Requesting Isolation

- Isolation in Force Electrical/Mechanical.

0.2 Approving an Isolation Certificate

Unit Manager will review the proposed application and approve the Isolation Certificate

0.3 Execution of Isolation

The Isolator performs the isolation as required in the Isolation Certificate in accordance with PDO Isolation requirements.

0.4 Completion of Work

Authorization to remove isolations will not normally be granted until all associated work permits have been canceled and the worksite returned to the normal safe operating condition.

- PTW Holder fills Isolation Certificate to permit the Isolator to remove Isolation.

- Isolator removes Isolation and fills the IC.

- The Work Permit Administrator files the original of the IC.

0.5 De-isolation for Test

There are occasions when it may be preferred to fully or partly de-isolate before the permit is canceled, to do a planned and controlled test, e.g. leak test or test of motor rotation, rather than cancel and re-issue the permit and all associated isolations.

- The sequence of the de-isolation and re-isolation must be carefully planned and recorded on a step-by-step procedure.

- The planning shall be backed up by a thorough risk assessment.

- Each de-isolation and re-isolation must be recorded on the Isolation Certificate.

0.6 Extended term Isolation

When isolation becomes long term isolation then the following conditions apply:

- Where equipment has to be taken out of service due to repair or replacement

- Where there is no current PTW

- When it is identified on the latest PTW that the equipment has not been de-isolated.

The reason for the long-term Isolation must be stated on the certificate.

Long-term Isolation Certificates must be checked validated and initialized by the Responsible Person at intervals not exceeding 7 days.

Long-term isolations shall only be authorized for 3 months maximum. At the end of this period, the certificate will be signed off and the isolation will be checked by the Isolator to confirm both the requirement for continued isolation and that the isolation is still effective. A new EPI IC will then be filled and duly signed.

A copy of the EPI IC is to be kept in a designated binder when no work is carried out on the isolated equipment.

4. Definitions & Abbreviations

In this procedure, the following terms have the specific meaning described in this section.

| IC | Isolation Certificate |

| EPI | Extended Period Isolation |

| Isolation | Physical separation or disconnection with one or more barriers of a power source i.e. pneumatic, liquid or electrical. |

5. Flowchart